| Incoterm: | FOB |

|---|---|

| Min. Order: | 1 Set/Sets |

Basic Info

Generator Type: Alternator

Output Type: AC Three Phase

Certification: CE, ISO

Standard: Standard

Additional Info

Packaging: In cases

Brand: QNP

Transportation: Ocean,Land

Place of Origin: China

Certificate: ISO9001,CE

Port: Qingdao Port,Shanghai Port

Product Description

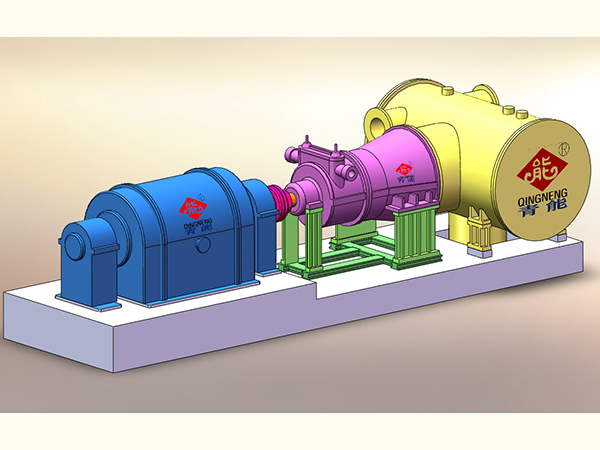

High Speed & High Efficiency Impulse Steam Turbine

The QNP steam turbines` capacity mainly covers 200MW and below, include NI series (Normal Impulse Turbines) and HE series (High Efficiency Turbines). Our steam turbines are flexible and diverse in structure and layout so as to meet various requirement of our users. Aiming at the global leading equipment manufacturing enterprise, our design and R&D standards are higher than GB standard and in the same league with European and American energy equipment manufacturers.

Characteristics of QNP Turbine:

Rotor: we have shrink-on rotor and solid forging structure rotor which are all processed by Mitsubishi Planer machine and adjusted by vacuum high speed dynamic balancing machine to make sure the vibration of each position of bearing is in good state when the steam turbine running. Small vibration of the rotor we produced is a distinctive characteristic of our products.

Condenser: the stainless steel screwed pipe is used as heat exchanger with good anti- pollution ability and high heat-exchange efficiency. High-quality titanium tube is used when the cooling water is seawater. We use digital controlled lathe for drilling hole.

Casing: the split is processed by one-off molding technology and the precision of which can be 0.0058MM without any steam leakage. The concentric circles of the whole axis are processed by high precision turn-milling of the 5-joint axis machining center.

Diaphragm: we use qualitative carbon steel as the support and make the flow field better comply with the design via special welding technology so as to improve the internal efficiency.

Lubricating oil system: the multiple filtration technology--impurity strainer of oil tank, double bucket strainer for refined filtration, bearing inlet strainer which can be replaced during running--make the turbine oil entering the bearing bush achieve the best performance.

Control and protection system: QNP uses the Siemens microprocessor as the core of the system to ensure the stability and timeliness of signal processing. For important signal, multistage redundancy functions are introduced to ensure the safe and stable operation of equipment. Friendly interface makes operator work easily. More than 3-monthes` record of operating data can be saved by recording system and also can be extracted at any time.

Various layout and application

Except the general double-tier layout structure, we also developed steam turbine with single-tier and fast-installation layout structure, mainly includes:

(1)Oil tank as base plate:

Company Overview:

Located in the Qingzhou city of Shandong province, QNP(QingNeng Power)has developed into the largest leading private manufacturer of steam turbines and generators in China, covering an area of 200,000 square meters with building area of 90,000 square meters. We have subsidiaries in Indonesia and Beijing, as well as a branch office in Shanghai.

QNP has passed such certificates as CE, ISO9000, ISO14001 and OHSAS18001.

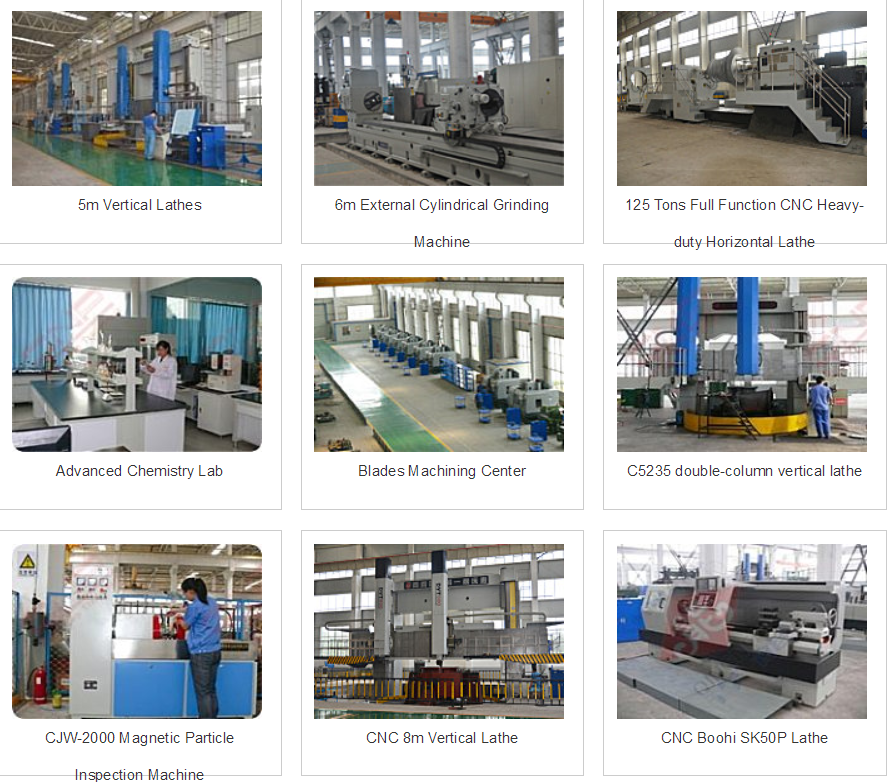

Manufacturing and Capacities:

With strong manufacturing and machining capacities, main parts and key components of our products are made by CNC machines. More than 400 types of advanced equipment with high accuracy, strong reliability and advanced machining processes are available with QNP, such as the Mitsubishi Planer five sides machining center, the Italy horizontal slotting machine, the 10 meters CNC heavy duty horizontal lathe, the 8 meters vertical lathe, the 6 meters CNC grinding machine, the CNC gantry milling and drilling machine, the CNC gantry wrapping machine and the winding machine for generators. The components are standardized and modularized with enhanced universality and compatibility.

Project Cooperate With Us:

Sales Network & After Sales:

The market share of QNP is growing steadily and rapidly. Our agents and products have a presence in many countries and regions all over the world such as the U.S.A, Canada, Brazil, Argentina, Russia, Australia, Serbia, India, Indonesia, Pakistan, the Philippines, Thailand, Cambodia, Vietnam, Iran, Myanmar, as well as Sudan, Morocco and Algeria in Africa.

QNP has a skilled and experienced After Sales team geared up for fast response and superior services to our customers at any time. Our Long distance monitoring center is equipped to monitor, diagnose, serve and manage the units delivered. QNP also provides technical training to our customers at regular intervals.

© 2019 CHINA WAY. All Rights Reserved. Shandong Qingneng Power Co., Ltd., Inc. All rights reserved. site map. sitemap.html